CNC Milling Service - Order Milled Parts Online

Simplify your CNC milling needs with meviy! Upload your 3D CAD file and instantly order customized milled parts online. Choose from a diverse selection of materials and surface treatments to match your project requirements. Enhance your CNC-milled parts with engraving options for a truly tailored solution. Experience fast, reliable, and efficient CNC milling services with meviy today!

Get Your First Part for FreeOrder Milling Machine Parts with meviy

Our Service for Milled Parts

Our service for milled parts ensures top-notch quality across all options, from material selection to surface treatments. Below, you will find detailed information about our extensive offerings, including materials like aluminum, steel, and plastics, and precise surface treatments such as anodising or plating.

Customise your milled parts with confidence, knowing they will meet the highest standards of accuracy and durability for any application.

- EN 1.0038 equiv.

- EN 1.0038 equiv. (flat bar)

- EN 1.0038 equiv. (annealed material)

- EN 1.1191 equiv. (flat bar)

- EN 1.1206 equiv.

- EN 1.1206 equiv. (20-27 HRC)

- NAK55 equiv.

- EN 1.4305 equiv.

- EN 1.4301 equiv.

- EN 1.4301 equiv. (flat bar)

- EN 1.4401 equiv.

- EN 1.4016 equiv.

- EN AW-2017 equiv.

- EN AW-5052 equiv.

- EN AW-6061 equiv.

- EN AW-6063 equiv.

- EN AW-7075 equiv.

- Polyacetal (standard, white)

- Polyacetal (standard, black)

- MC Nylon (standard, blue)

- MC Nylon (standard, ivory)

- MC Nylon (black ash)

- Bakelite (paper, natural colour)

- Bakelite (paper, black)

- Bakelite (coth, natural)

- Fluorine (standard, white)

- UHPE

- UHPE (conductivity, black)

- ABS (standard, natural colour)

- PEEK (standard, grey-brown)

- Black Oxide

- Electroless nickel plating

- Hard Chrome Plating (Flash Plating)

- Trivalent Chromate (clear)

- Trivalent Chromate (black)

- Clear anodized

- Black anodized

- Black anodized (matt)

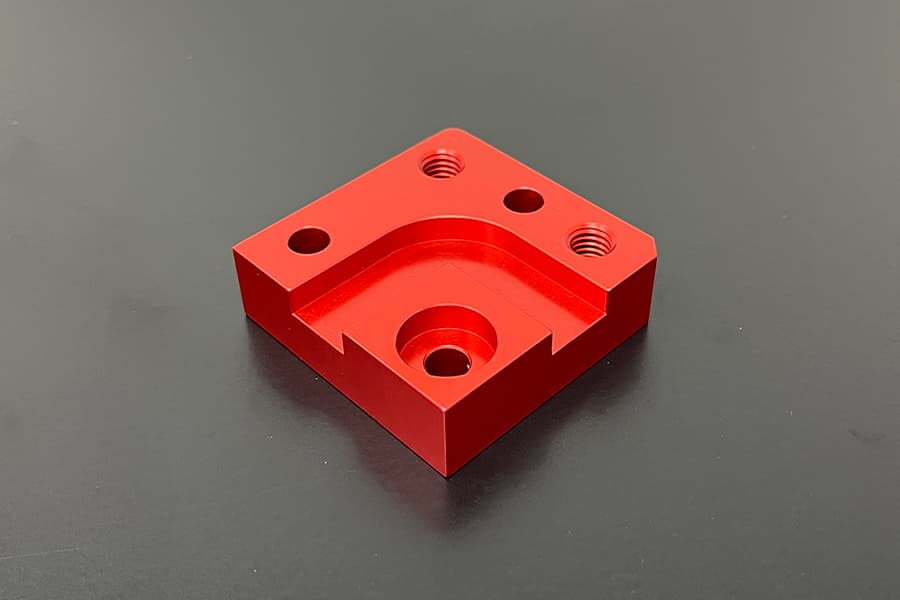

- Red anodized

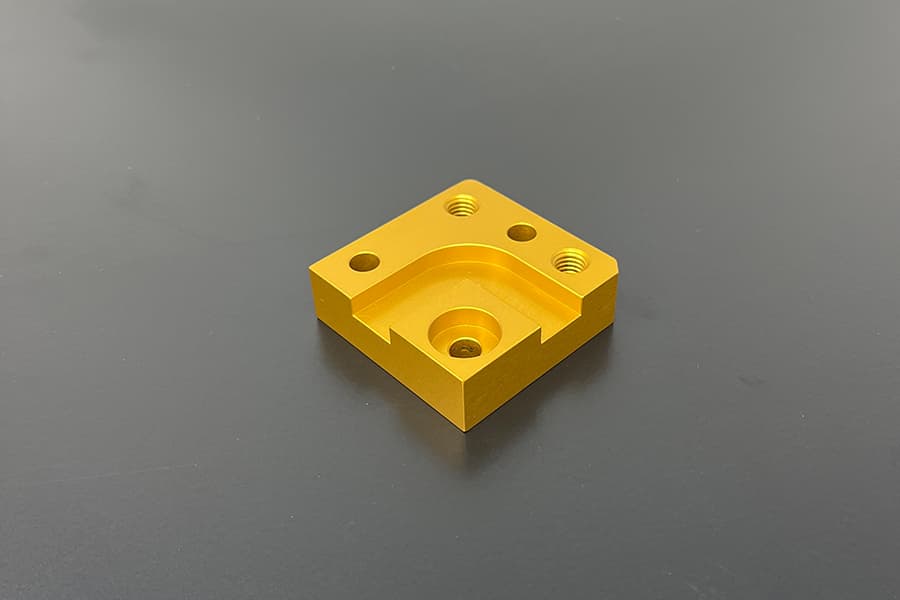

- Gold anodized

You can find more detailed information on our range of materials and surface treatments in our specifications.

Introduction to CNC milling

The CNC (computer numerical control) milling is an important process of milling machine parts in modern manufacturing technology. Milling involves removing material from a workpiece using rotating cutting tools to manufacture complex shapes and precision components. These CNC machines offer numerous advantages over manual processes. Through automation, more precise and repeatable results can be achieved, leading to improved product quality and efficiency in manufacturing.

The milling machines work according to predefined programs, called CAM systems (computer-aided manufacturing), which control the movements of the tool. These programs are created using CAD software and contain PMI (product manufacturing information) about the parts to be manufactured and the required milling operations. There are different types of milling tools that are used depending on the requirements of the workpiece and the desired surface finish. Common tools include end mills, face mills and ball nose end mills.

The choice of material is an important aspect of milling. Various materials such as metals, plastics and composites can be processed. The right choice of material and the adjustment of cutting speeds are decisive for the quality of the machining and the service life of the tools. Milling technology is used in various industries, including the automotive industry, aerospace, electronics and medical technology. It enables the manufacture of precise parts and components for complex devices and machines.

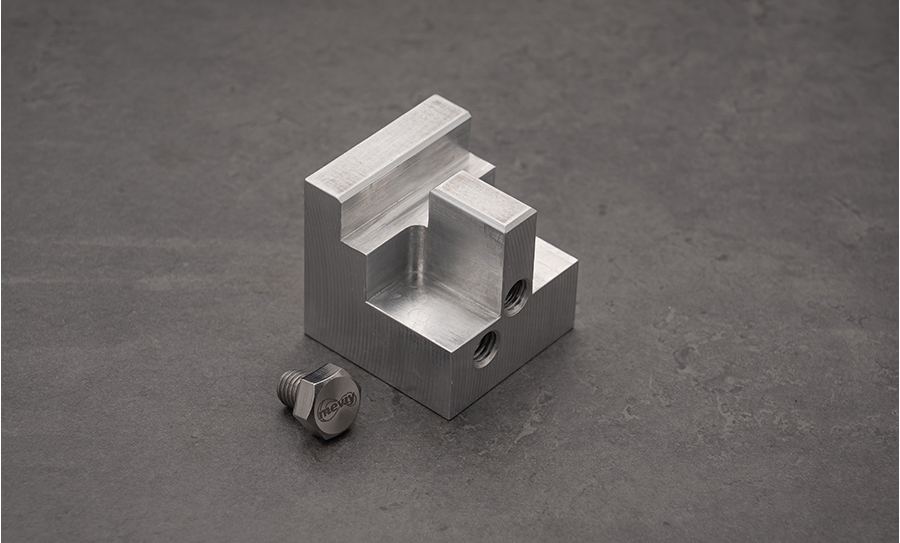

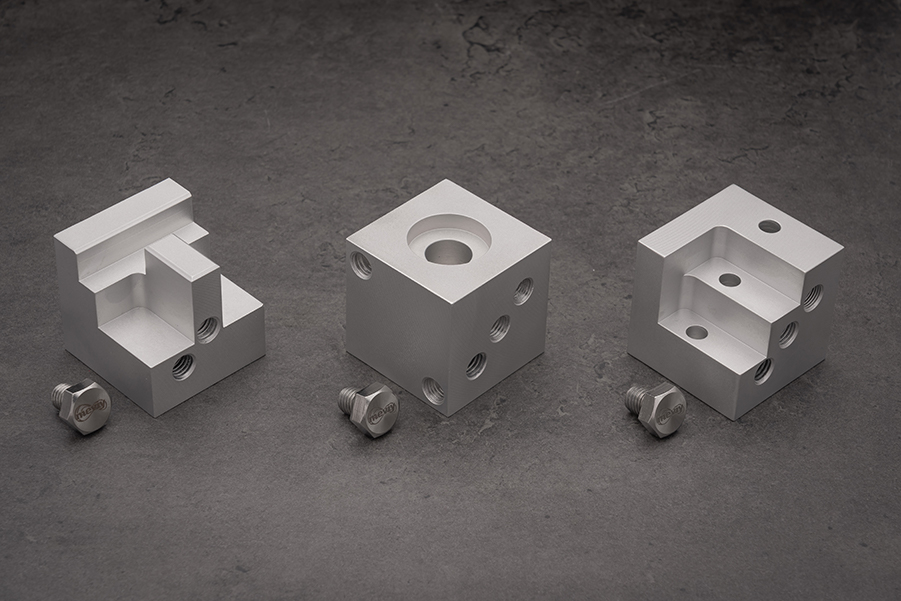

Milled Parts Manufactured to the highest Quality with meviy

Welcome to our slideshow of precision-crafted milling machine parts! Manufactured with advanced CNC technology, these parts deliver exceptional quality and performance for a wide range of applications.

Discover the versatility of our milling machine parts, available in various materials and finishes. Designed for accuracy and durability, they’re perfect for projects demanding top-notch precision and reliability.

CNC Milling - Frequently Asked Questions (FAQ)

1. What is CNC Milling?

CNC milling is a precise manufacturing process that uses rotating cutting tools to remove material from a workpiece. Controlled by a computer, this method allows for the production of complex shapes and high-precision components. It is commonly used to create milling machine parts, ensuring accurate dimensions and surface treatments for a variety of industries and applications.

2. What are milled parts?

CNC milled parts are precision components created using computer-controlled milling machines. Material is carefully removed from a workpiece to form intricate shapes and smooth surfaces. These milled parts are essential in industries such as mechanical engineering, medical technology, and automotive manufacturing, where high accuracy and reliability are crucial.

3. Which materials can be processed with CNC milling?

Various materials can be processed using CNC milling, including metals such as aluminium, steel, stainless steel and titanium as well as plastics, wood and composite materials. The choice of material depends on the specific requirements of the end product. meviy currently offers the materials steel, stainless steel, aluminium and plastic for CNC milling.

4. What are the advantages of CNC milled parts?

CNC milled parts offer high precision, repeat accuracy, and the ability to manufacture complex shapes with tight tolerances. One key advantage of milled parts is their versatility in producing both small and large production runs efficiently. Additionally, the CNC process allows for consistent quality across all units, making it ideal for industries requiring high reliability and complex geometries. The automation of the process also reduces human error and increases overall productivity.

5. In which industries are CNC milled parts used?

CNC milled parts are used across a wide range of industries, including automotive, aerospace, medical technology, electronics, and mechanical engineering. These parts are essential for producing high-precision components such as engine parts, surgical instruments, and electronic housings. Due to their versatility, milled parts are also critical in sectors like robotics and energy, where exact specifications and reliability are required for both small and large-scale production.

6. How precise is CNC milling?

CNC milling offers exceptional precision, often reaching micrometer-level accuracy. This makes it ideal for applications requiring tight tolerances, such as in aerospace or medical technology. The process ensures consistent results, allowing for the creation of intricate, high-quality parts with minimal deviation. CNC milling's precision is a key factor in industries where reliability and exact specifications are critical, ensuring the functionality and safety of complex components.

7. What does it cost to manufacture CNC milled parts?

The cost of manufacturing milled parts depends on several factors, including material choice, design complexity, tolerances, and order quantity. While milled parts produced through CNC milling can be more expensive than traditional methods, the process offers higher precision and efficiency. These advantages often lead to long-term savings, especially in custom or small-batch production, due to reduced waste and faster turnaround times for complex designs.