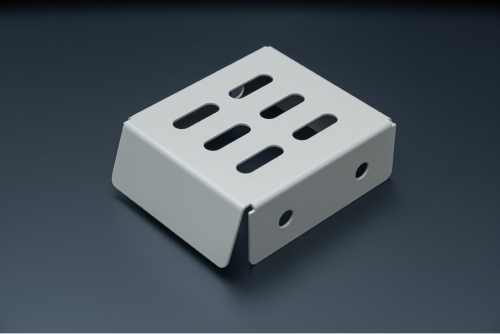

Order your Finished Sheet Metal Parts

With meviy, you can order your specific sheet metal parts quickly and easily online by uploading your 3D CAD file. Discover the advantages of surface treatments and where they are preferably applied. Finish your sheet metal parts with meviy.

Get an instant quoteFinishing options for sheet metal parts

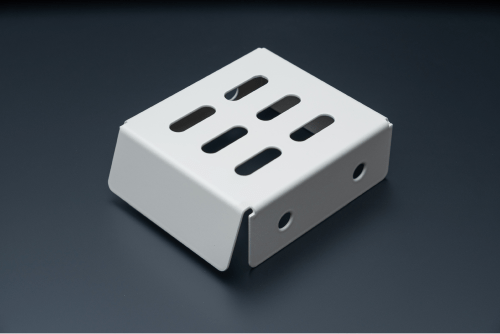

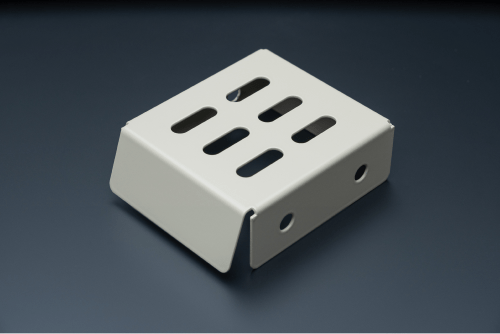

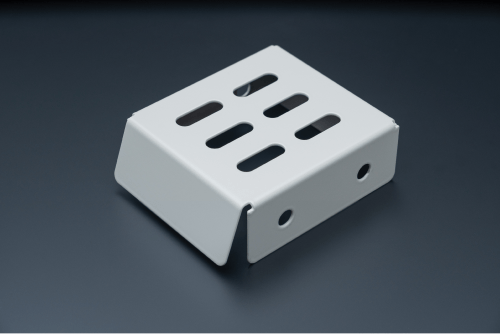

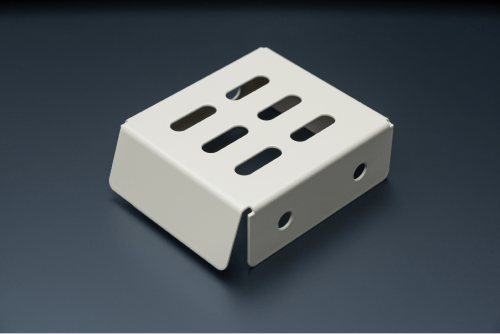

Surface treatment plays a crucial role in various industries as it is an essential step in improving the performance, durability and aesthetics of materials. From finishes such as anodizing of metals to coatings such as powder coating, our manufacturing services offer a variety of processes designed to specifically modify the properties of surfaces. (Coating of plastics is not possible)

In this context, we present a detailed overview of all available surface treatments from meviy. Our diverse techniques and processes make it possible not only to make materials more aesthetically pleasing, but also to improve their functionality and durability. Discover the various surface treatment options and find the optimum solution for your individual requirements and applications.

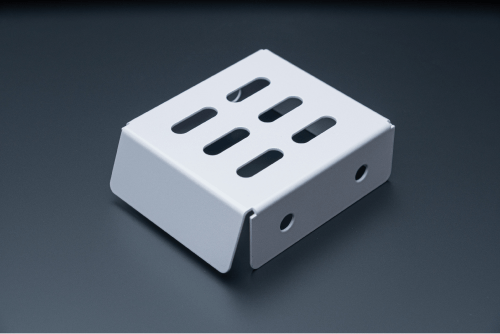

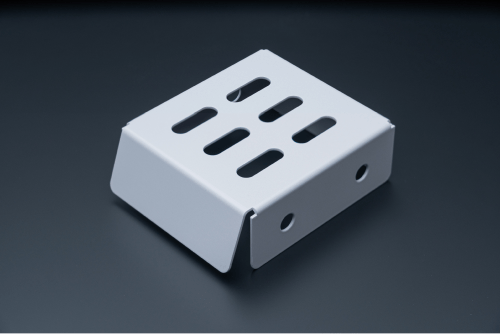

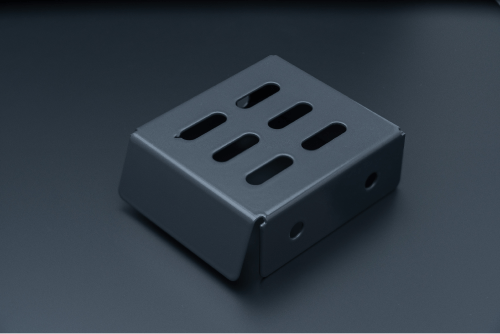

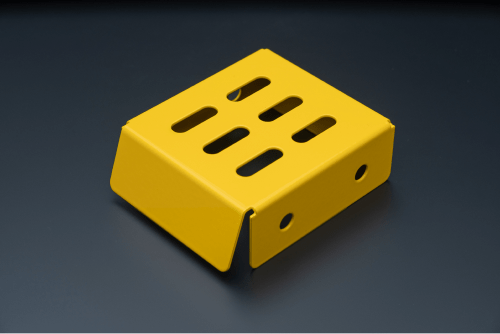

Colours for Powder Coating

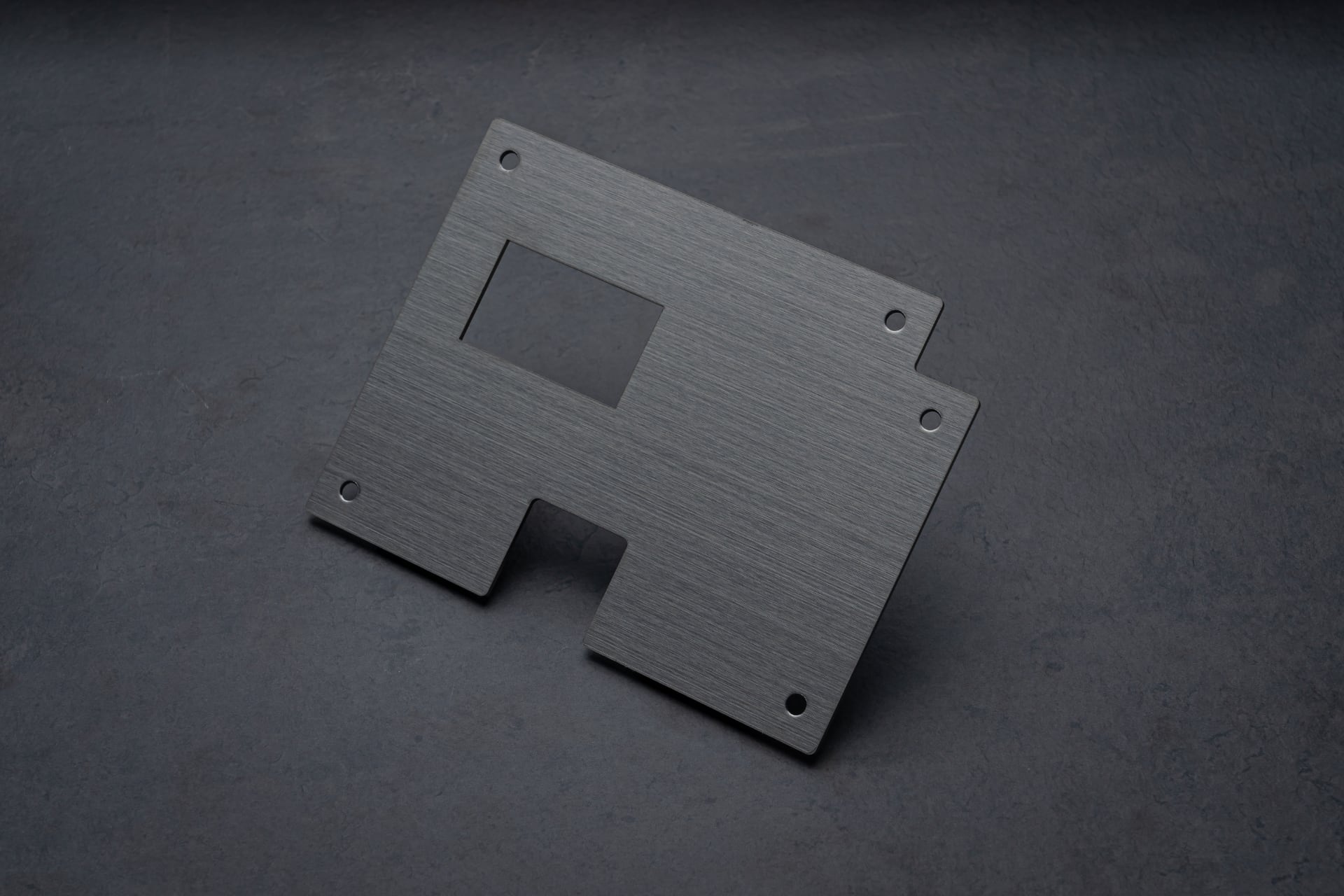

Hairline Finish

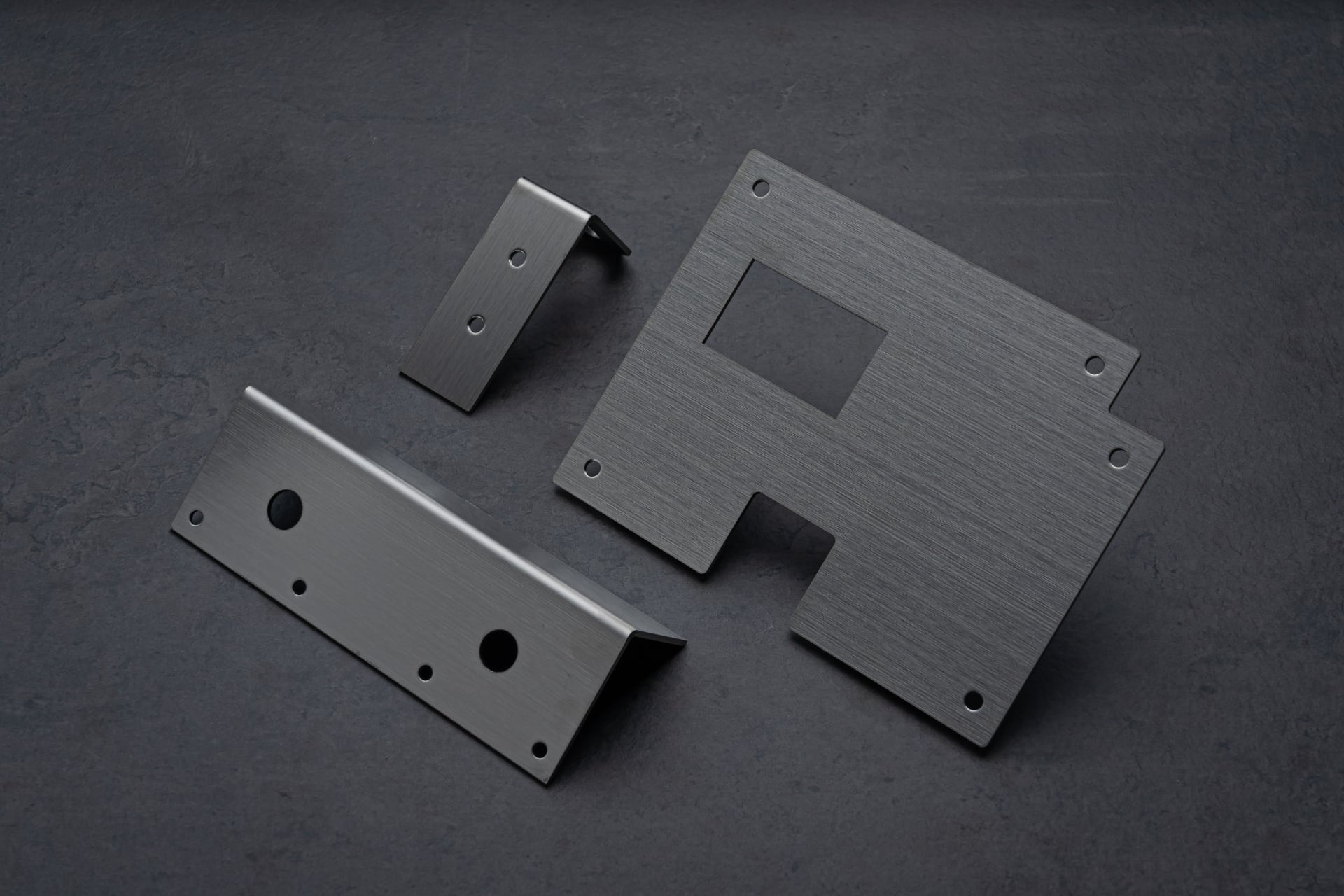

Hairline finish is a special surface finishing technique used in various industries such as metalworking, architecture and the manufacture of consumer goods. This technique creates fine and even lines on the surface of the material, resulting in an elegant and attractive finish.

For example, EN 1.4301 equiv. has a visible, hairline finish on the surface, as shown in the figure above. The polishing direction of the hairline finish is called "One-sided fine line structure", and in the meviy service, the machining direction of the drawing created by expanding the 3D model shape is used as the machining direction. If you want to use a different processing direction, please contact meviy support for a quote.