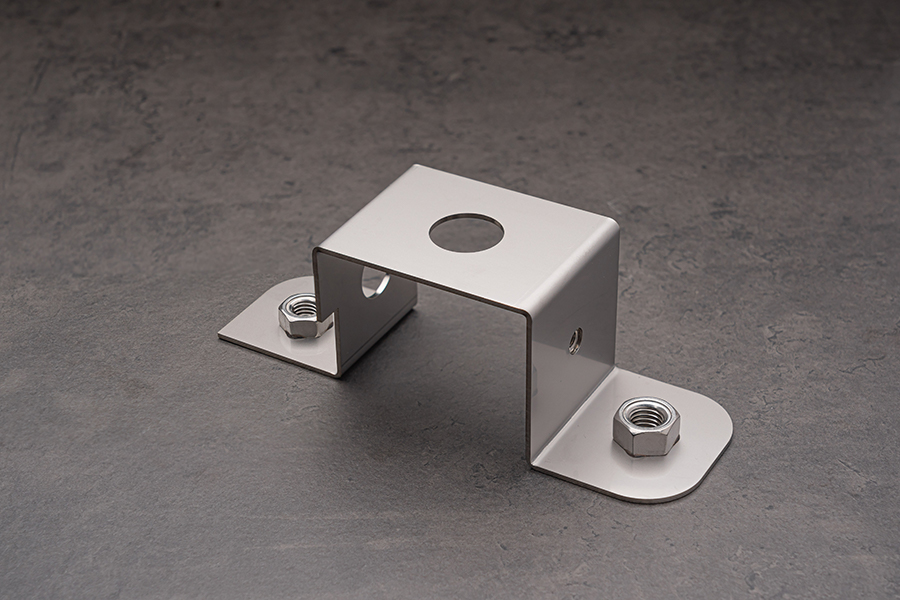

Instant Quotation for your Sheet Metal Parts

With meviy, you can order your custom sheet metal parts quickly and easily online by uploading your 3D CAD file. Below you will find general tips on the design of your sheet metal parts and how you can design them more efficiently and cost-effectively.

If you still have questions about meviy, please contact our meviy support.

Typical Errors when creating a Quote with meviy

The uploaded 3D CAD file could not be read by meviy

If you encounter this error

1. the file format could not be read

2. PMI could not be calculated

this means that you are using 3D CAD formats and extensions that are not supported by meviy. To solve this problem, we recommend that you check and adjust the list of formats supported by meviy.

- Autodesk Inventor 2023 + previous versions (.ipt)

- CATIA V5-6R2022 + previous versions (.CATpart)

- Creo - Pro/E 19.0-Creo 9.0 (.prt/.neu/.xpr)

- NX - Unigraphics (.prt)

- SolidEdge V19-20/ST10 + previous versions (.par/.pwd)

- SOLIDWORKS 2023 + previous versions (.sldprt)

- I-deas (.arc/.unv)

- iCAD SX V8L3 + previous versions (.icd)

- STEP AP203, AP214 (.step/.stp)

- Parasolid (.x_t/.x_b/.xmt/.xmt_txt)

- ACIS (.sat/.sab)

- JT (.jt)

- PRC (.prc

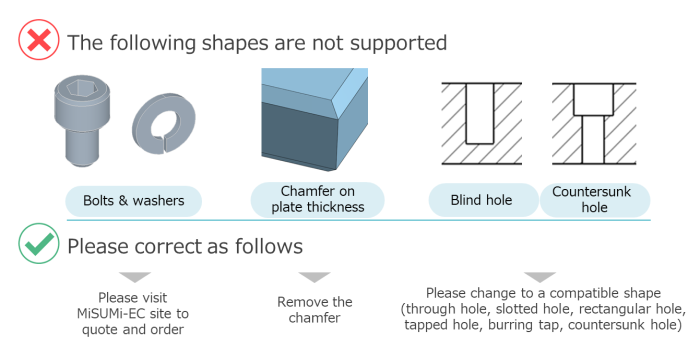

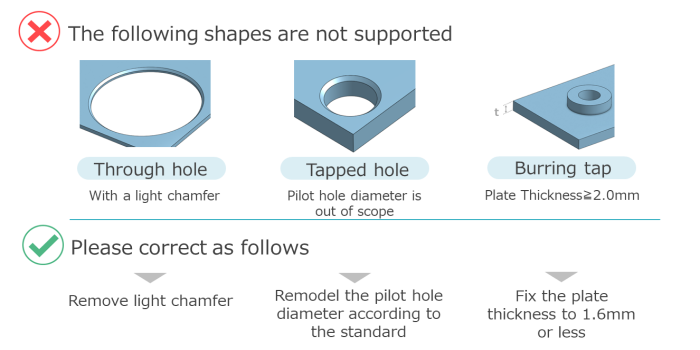

Unsupported shape

This error is caused by uploading a form that is not available for an automatic quote with meviy. To resolve this issue, please check the available shapes that we can offer with meviy.

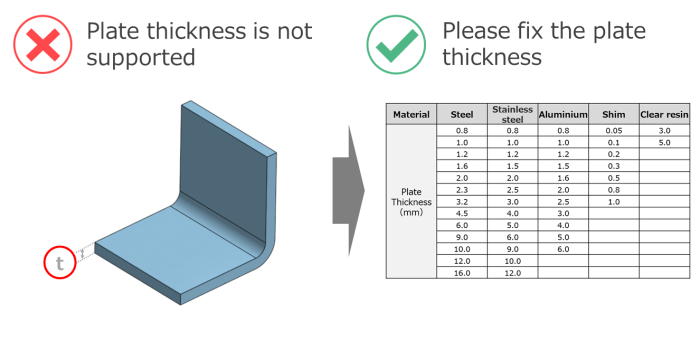

Unsupported thickness

This error occurs if the desired sheet thickness is not supported. To solve this problem, please adjust the model so that it matches the available sheet thickness.

Non-uniform sheet thicknesses

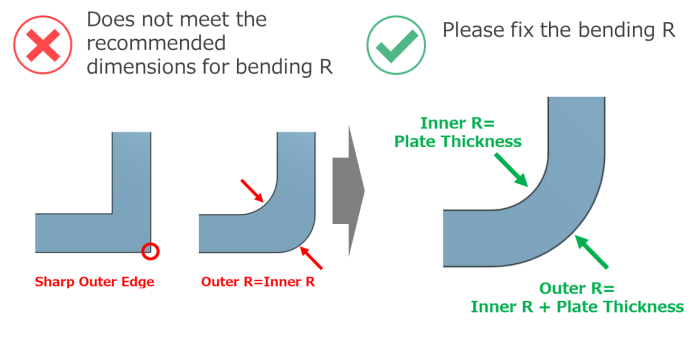

This error occurs if the sheet thickness is not constant during the creation of the part or if the creation of the radius R is not within the possible range. To solve this problem, please adjust the model so that the sheet thickness is uniform.

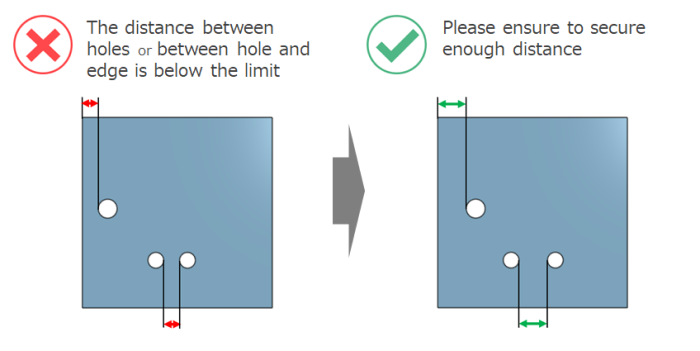

Distance between holes is too small

This error occurs if the distance between the holes and the edge or between the holes is below the possible range. To solve this problem, please increase the distance between the holes and the end faces or between the individual holes.

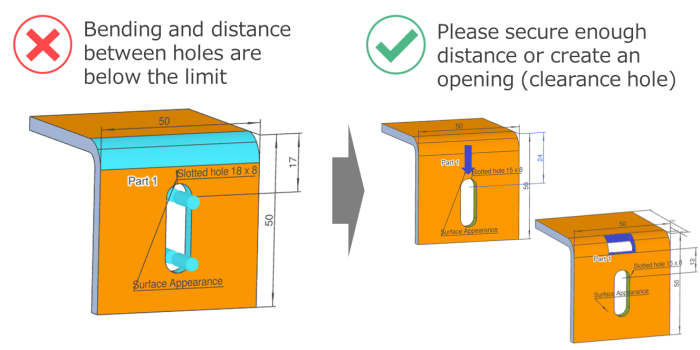

Distance from bend to hole

This error occurs if the distance between the bend and the hole is below the limit value. To rectify this problem, either increase the distance between the bend and the hole or create an opening at the bending edge (cut-out).

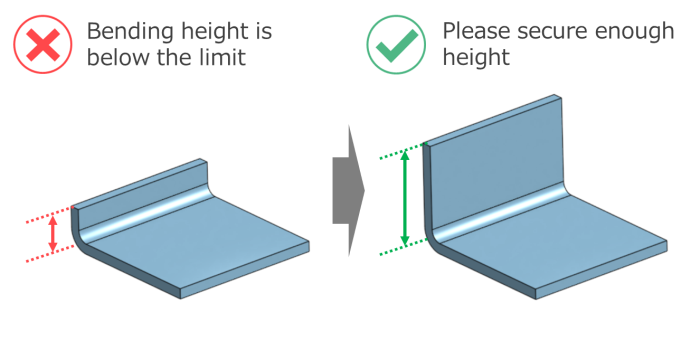

Bending height too low

This error occurs if the bending height is below the limit value. To rectify this problem, increase the bending height to a suitable dimension. Detailed information on the dimensions can be found on our technical information page.

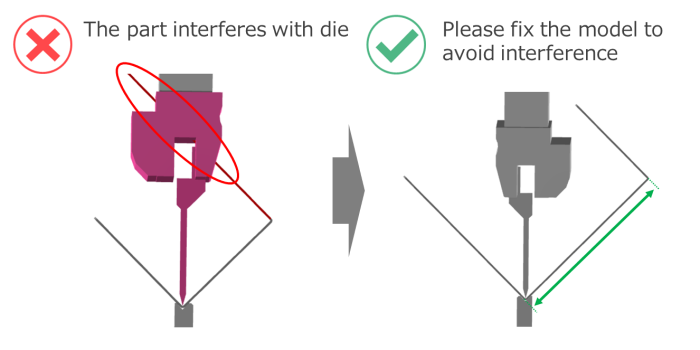

Fault during bending

This error occurs when the component geometry causes interference during bending. To correct this problem, adjust the part in your 3D CAD file to avoid the interference. You can find detailed help on our technical information page.

Hole shape not recognized

This error occurs if the shape of the hole is not recognized. To fix this, please change the hole to a supported shape and upload the file again.

Rules for modeling when bending sheet metal

Bending

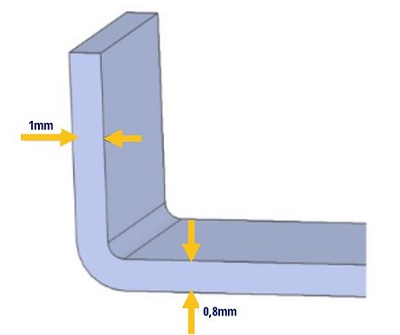

The sheet thickness is not uniform

The sheet thickness must be the same on both sides. In the example on the left, you can see a bent sheet metal part with a sheet thickness of 1 mm on one side and 0.8 mm on the other. In order to receive a quote for this sheet metal part and to be able to manufacture it, both sides must have the same sheet thickness. For example, 0.8mm or 1mm on both sides. Please check your 3D CAD file and upload the part to meviy again.

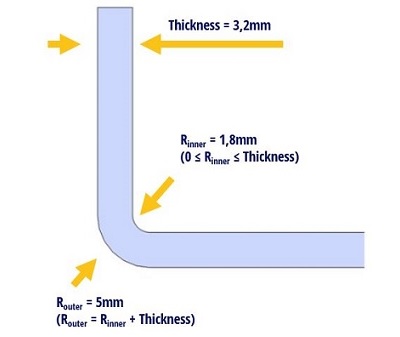

Determination of the radius

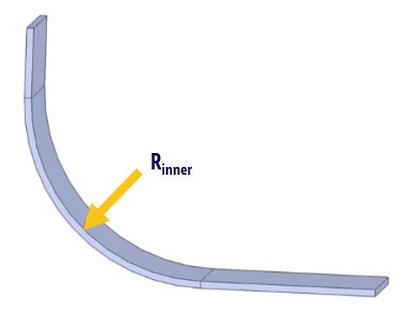

Always model the inside radius (Rinside) of the bend as follows:

0 ≤ inner radius ≤ sheet thickness.

The inner radius must also be smaller than the sheet thickness. Both values together should result in the outer radius (Routside).

Routside = inside radius Rinside + sheet thickness

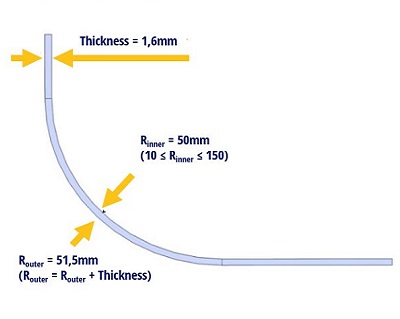

Feed bending

Determination of the radius during feed bending

The inner bending radius should be at least 10, while the outer bending radius should correspond to the inner radius plus the sheet thickness. Please refer to the following section for the range of bending radii.

The sheet thickness is not uniform

The sheet thickness must be the same on both sides. In the example on the left, you can see a bent sheet metal part with a sheet thickness of 1 mm on one side and 0.8 mm on the other. In order to receive a quote for this sheet metal part and to be able to manufacture it, both sides must have the same sheet thickness. For example, 0.8mm or 1mm on both sides. Please check your 3D CAD file and upload the part to meviy again.